BLOG

Top Applications of Plastic Injection Molding in Various Industries?

Plastic injection molding is a widely used manufacturing process across many industries. Its ability to create complex shapes and designs makes it invaluable. With this technique, manufacturers can produce high volumes of parts with precision and consistency.

In the automotive sector, plastic injection molding produces various components, like dashboard panels and interior fittings. These parts are lightweight, which improves fuel efficiency. Similarly, in the medical industry, this process creates crucial devices, such as syringes and surgical tools, that require strict adherence to safety standards.

However, not all applications highlight the advantages of plastic injection molding. Issues can arise with waste and recycling. While the method is efficient, it often leads to surplus material that isn't reused. The industry is reflecting on ways to minimize its environmental footprint. Addressing these challenges is essential for future growth and sustainability.

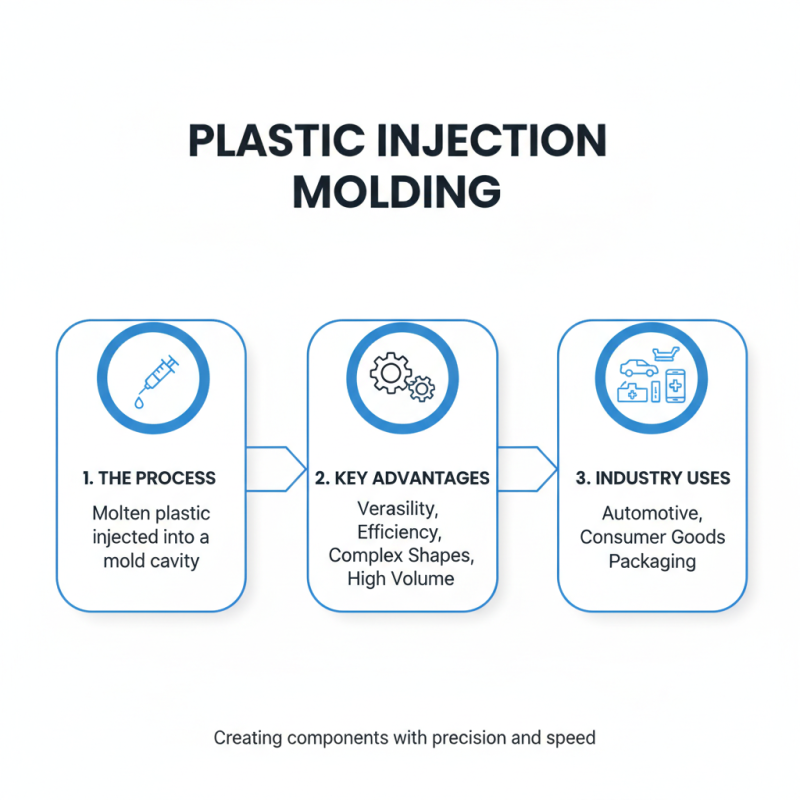

Overview of Plastic Injection Molding Technology

Plastic injection molding is a widely used manufacturing process. It involves creating parts by injecting molten plastic into a mold. This method is favored due to its versatility and efficiency. Different industries rely on this technology for their production needs. It is capable of producing intricate designs and complex shapes, which is essential in today's competitive market.

One notable advantage of plastic injection molding is its speed. This process can produce large volumes of parts quickly. However, this speed can lead to issues. For example, the quality of the final product might suffer if not monitored carefully. Even minor variations in temperature can affect the outcome. Additionally, maintaining the molds can be costly, which impacts production budgets.

In various industries, plastic injection molding serves specific purposes. It is used in automotive components, consumer goods, and medical devices. Each application has unique requirements that challenge manufacturers. The need for precision often clashes with production pace. Finding the right balance is crucial but can be difficult. This technology continues to evolve, but challenges remain. The quest for improvement is ongoing.

Key Industries Utilizing Plastic Injection Molding

Plastic injection molding is a vital process across numerous industries. The automotive sector heavily relies on it for producing parts such as bumpers and dashboards. These components require precision and durability. Molding allows manufacturers to create intricate designs that blend form and function efficiently. However, there's often a gap between design intentions and production reality. Quality control can be a challenge.

In the consumer goods industry, plastic injection molding shapes everyday products. Items like containers, toys, and household tools emerge from this process. Each product needs to meet safety standards and consumer expectations. Yet, sometimes the finish isn't perfect. Aesthetic flaws or minor defects can slip through the cracks. This can lead to regrets later on.

Healthcare is another crucial field utilizing this technique. Medical devices and equipment often benefit from molded plastic. The lightweight yet robust nature of these items is essential in patient care. Still, the pressure for innovation can overshadow quality. Companies may rush prototypes, risking performance issues. This reflects a broader trend where speed sometimes trumps thoroughness in manufacturing.

Innovations in Plastic Injection Molding Applications

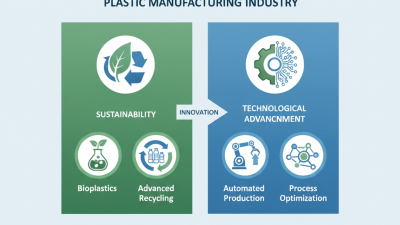

Plastic injection molding continues to evolve, making significant strides across various industries. Innovations in technology enhance efficiency and precision. For instance, advancements in 3D printing have streamlined mold creation processes. This leads to faster production times and reduced costs. However, one must consider the environmental impact of increased plastic use. It's crucial to balance innovation with sustainability.

Furthermore, the development of new materials has broadened the scope of applications. Bio-based plastics are emerging, offering alternatives to traditional petroleum-based options. These materials can reduce carbon footprints, yet their durability is still under scrutiny. It's necessary to address these challenges to ensure viability in long-term use.

Another interesting trend is automation in molding processes. Robotics are becoming integral, increasing production rates while minimizing human error. However, this transition can raise concerns about job displacement in the workforce. Reflecting on these developments reveals a complex landscape of opportunity and responsibility. As the industry progresses, maintaining an ethical approach remains vital.

Environmental Impact and Sustainability in Injection Molding

Plastic injection molding is widely used across various industries. However, its environmental impact raises significant concerns. The process involves melting plastic and injecting it into molds. This energy-intensive process can lead to high carbon emissions. Many manufacturers are now looking for ways to reduce their eco-footprint.

Sustainability is a growing focus in the field. Some companies are experimenting with biodegradable plastics. These materials can decompose more naturally than traditional plastics. Recycling programs are also on the rise. Yet, challenges remain in the recycling rates of injected molded products. Not all plastics are recyclable, and this often leads to increased waste.

There's a need for more awareness around the lifecycle of plastic products. Consumers are demanding transparency. They want to know how their choices impact the environment. Innovations in machine efficiency and material sourcing must progress. As the industry evolves, it’s important to keep reflecting on these impacts for a better future.

Top Applications of Plastic Injection Molding in Various Industries

This chart illustrates the various applications of plastic injection molding across different industries, showcasing their respective market share percentages. The data reflects the increasing use of sustainable practices in these sectors.

Future Trends and Developments in Plastic Injection Molding

The future of plastic injection molding shows promising trends driven by technological advancements. Industry reports suggest a compound annual growth rate (CAGR) of 5.4% in the plastic injection molding market, expected to reach $482.6 billion by 2028. Automating processes boosts efficiency and reduces errors, yet manufacturers must stay vigilant about potential job losses in manual production roles.

Sustainability will be a significant focus for the industry. More companies are exploring biodegradable materials and recycling methods. A recent survey indicated that 70% of manufacturers believe sustainable practices will influence purchasing decisions. However, transitioning to greener processes isn't always straightforward. It requires investment and time, often leading to initial setbacks in production rates.

Tips: Consider integrating smart technologies for real-time monitoring. This can improve quality control significantly. Also, evaluate the lifecycle of materials. Sustainable choices may have upfront costs but can save money over time. Lastly, engage with your team. Encourage feedback on new materials and processes, as this can lead to innovative solutions.

Related Posts

-

Top Insights on Plastic Manufacturing Industry Trends and Innovations

-

How to Choose the Right Plastic Inc Company for Your Needs?

-

Exploring the Future of Injection Tooling Innovations and Trends

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

How Custom Injection Molded Parts Revolutionize Modern Manufacturing Techniques

-

How to Choose the Right Molding Plastic for Your Next Project

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com