BLOG

Top Insights on Plastic Manufacturing Industry Trends and Innovations

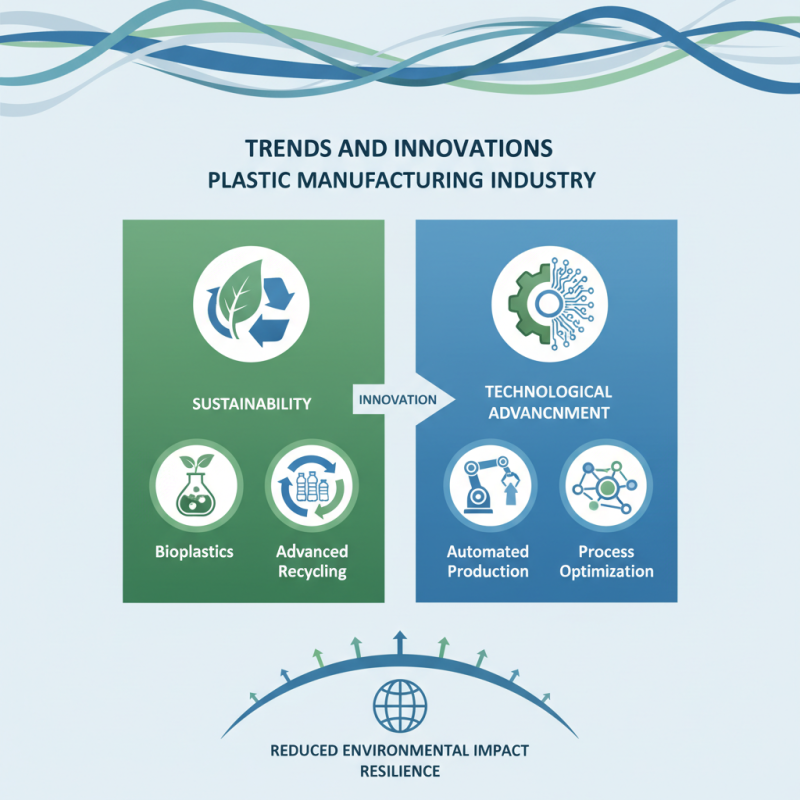

The plastic manufacturing industry is undergoing a dynamic transformation, driven by innovations and emerging trends that are reshaping the landscape. As highlighted by industry expert John Smith from Plastic Inc, "The future of plastic manufacturing lies in sustainability and technological advancement." This statement reflects the growing emphasis on environmentally friendly practices and cutting-edge technologies that are becoming integral to the sector.

With the increasing demand for sustainable materials and solutions, manufacturers are exploring bioplastics and recycling methodologies that not only meet market requirements but also mitigate environmental impact. As the industry adapts to these trends, innovations in production processes are paving the way for enhanced efficiency and reduced waste. The insights gathered from key players within the industry suggest a collective shift towards a more responsible and innovative approach to plastic production.

In this rapidly evolving landscape, staying informed about the latest trends and technological advancements is crucial for stakeholders across the plastic manufacturing spectrum. Understanding these shifts not only aids in strategic planning but also fosters a culture of innovation that drives the industry forward, ensuring that it remains resilient in the face of environmental challenges.

Current Trends in Plastic Manufacturing: An Overview

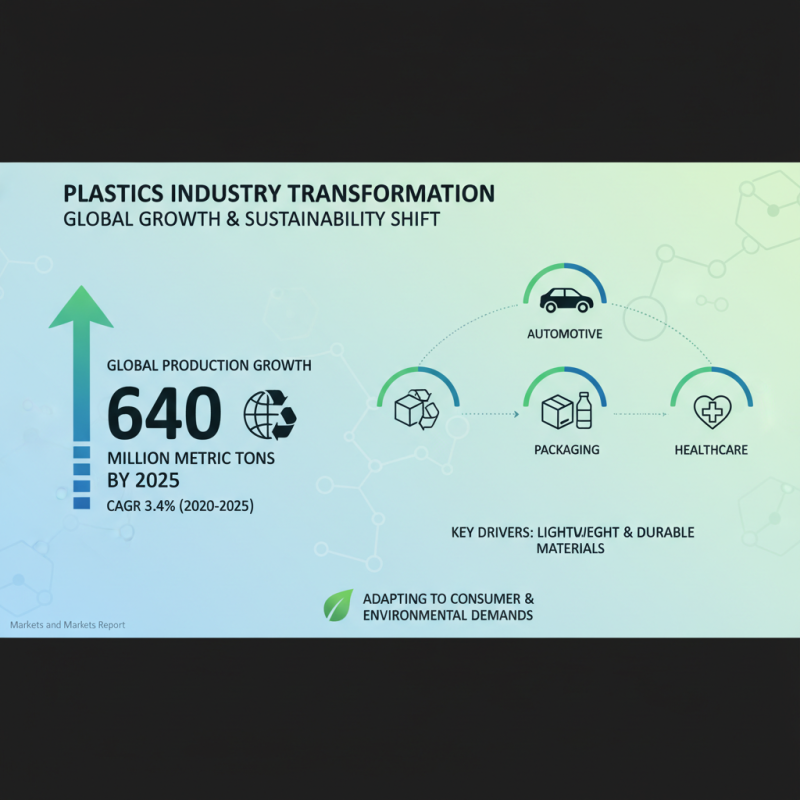

The plastic manufacturing industry is undergoing significant transformations as it adapts to emerging consumer demands and environmental responsibilities. According to a report from Markets and Markets, the global plastic production is expected to reach approximately 640 million metric tons by 2025, reflecting a compound annual growth rate (CAGR) of 3.4% from 2020. This growth is driven by increasing applications in various sectors such as automotive, packaging, and healthcare, where the demand for lightweight and durable materials continues to rise.

Current trends indicate a pronounced shift toward sustainability within plastic manufacturing. The adoption of bio-based and biodegradable plastics is gaining momentum, fueled by regulations aimed at reducing plastic waste and encouraging recycling. A study by the European Bioplastics organization estimates that the bioplastics market could reach 2.43 million tons by 2024, a notable increase from 2.11 million tons in 2019. This trend is not only redefining material sourcing and processing techniques but is also pushing manufacturers to innovate in recycling technologies, with an emphasis on closed-loop systems that minimize environmental impact while maximizing resource efficiency. The industry is investing in advanced manufacturing processes, such as 3D printing and smart production lines, to enhance operational efficiency and adaptability to market needs.

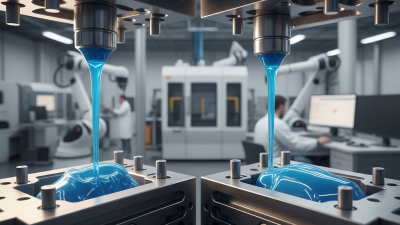

Innovative Technologies Shaping the Future of Plastic Production

Innovative technologies are transforming the plastic manufacturing industry, paving the way for more sustainable and efficient production methods. A key trend is the adoption of additive manufacturing, commonly known as 3D printing, which allows for the rapid prototyping and production of complex plastic components. This technology reduces waste significantly by using only the material needed for each prototype, thus optimizing resource usage. Moreover, advancements in bioplastics are becoming increasingly prevalent, as manufacturers seek to create environmentally friendly alternatives to traditional petroleum-based plastics. By utilizing renewable materials, the industry aims to mitigate its impact on the environment.

Another noteworthy trend is the integration of automation and smart technologies within production lines. The implementation of IoT (Internet of Things) devices and AI-driven analytics is enhancing operational efficiencies and enabling predictive maintenance. This technology helps manufacturers monitor equipment performance in real-time, reducing downtime and increasing productivity. Furthermore, the use of data analytics allows for better decision-making processes, enabling manufacturers to fine-tune their operations for increased efficiency and reduced costs. As these innovations continue to evolve, the plastic manufacturing industry is well-positioned to embrace a more sustainable and technologically advanced future.

Sustainability Practices in the Plastic Manufacturing Industry

The plastic manufacturing industry is increasingly prioritizing sustainability as a response to growing environmental concerns and regulatory pressures. Companies are adopting innovative practices aimed at reducing waste and minimizing carbon footprints. This trend includes investment in recycling technologies and the use of bio-based materials that can help decrease reliance on fossil fuels. Emphasis is also being placed on designing products for longevity and recyclability, ensuring that materials can be repurposed at the end of their lifecycle instead of contributing to landfill waste.

Moreover, the integration of circular economy principles is becoming a focal point in the industry. This approach encourages the continuous use of resources and aims to eliminate waste by circulating products through various life stages. Manufacturers are collaborating more with stakeholders and suppliers to develop closed-loop systems, wherein post-consumer plastics are collected, reprocessed, and transformed back into raw materials for new products.

These sustainability practices not only meet consumer demand for greener alternatives but also foster innovation within the industry, driving advancements in material science and production efficiencies.

Consumer Demand and Its Impact on Plastic Manufacturing Trends

Consumer demand plays a pivotal role in shaping the trends and innovations within the plastic manufacturing industry. As society increasingly prioritizes sustainability, there is a growing expectation for manufacturers to adopt eco-friendly practices. This shift is prompting companies to explore bioplastics and recycled materials as viable alternatives to conventional plastics. By responding to consumer preferences for sustainable products, manufacturers not only enhance their market appeal but also align with global environmental goals.

Moreover, the impact of consumer technology on purchasing behavior cannot be overlooked. With the rise of e-commerce and digital platforms, consumers are more informed and discerning. They seek products that are not only functional but also reflect social responsibility. This trend has led manufacturers to invest in advanced production techniques that incorporate life-cycle assessments and transparency in sourcing materials. As a result, the plastic manufacturing sector is evolving, driven by the necessity to meet these expectations while remaining competitive in a fast-paced market.

Trends in Consumer Demand and Their Impact on Plastic Manufacturing

Challenges Facing the Plastic Manufacturing Sector Today

The plastic manufacturing sector is currently navigating a complex landscape marked by several significant challenges. According to a report by the Plastics Industry Association, nearly 70% of manufacturers have reported supply chain disruptions in recent years. These disruptions have been exacerbated by the COVID-19 pandemic, leading to rising raw material costs and inconsistent availability of key inputs. Such instability forces manufacturers to rethink their sourcing strategies and inventory management, making it imperative to diversify suppliers and adopt more resilient supply chain practices.

Additionally, the plastic manufacturing industry faces increasing pressure to adopt sustainable practices amid growing environmental concerns. A recent study by McKinsey & Company found that approximately 50% of consumers are willing to pay more for sustainable products, compelling manufacturers to innovate towards biodegradable and recyclable materials. However, transitioning to more sustainable practices presents technical and financial hurdles, with initial investments in research and development often surpassing those for traditional production methods. As the regulatory landscape evolves, companies must not only comply with stricter regulations but also invest in new technologies to enhance their sustainability efforts while maintaining competitiveness in a rapidly changing market.

Related Posts

-

How to Choose the Right Plastic Company for Your Manufacturing Needs

-

Exploring the Future of Injection Tooling Innovations and Trends

-

Understanding the Role of Plastic Injection Companies in Sustainable Manufacturing Practices

-

How Custom Injection Molded Parts Revolutionize Modern Manufacturing Techniques

-

Understanding the Plastic Injection Moulding Process for Efficient Manufacturing

-

Top 10 Benefits of Injection Tooling You Need to Know About

Our Promise to You

All products and services provided by Innovative Plastic Molders, Inc. will meet or exceed our customer's perceived requirements and expectations. We will listen and respond to what our customers are telling us in a timely and forthright manner.

ISO 9001:2015 CERTIFIED

© Copyright 2009 – Innovative Plastic Molders, Inc.

Website by Central 8 Marketing

Contact IPM

10451 Dog Leg Road Ste 200

Vandalia, OH 45377

Phone: 937.898.3775

Fax: 937.535.0640

Email: sale@endtheplastic.com